Project Description

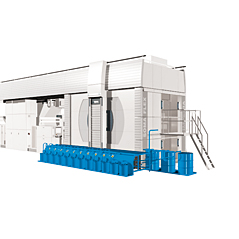

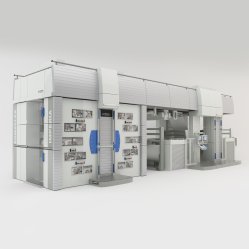

The PREMIA model offers a unique combination of features and technology usually reserved for high performance, top of the range flexographic printing presses. High on our list of priorities was the need to design a machine good enough to meet exacting print standards while reducing energy consumption and costs. The energy efficient PREMIA achieves this and offers a superb mix of high quality engineering and rigid construction coupled with low maintenance.

Key Features

- Printing decks8

- Print width820 / 1050 / 1270 /…

- Print length300 – 915 mm

- Speed500 m/min

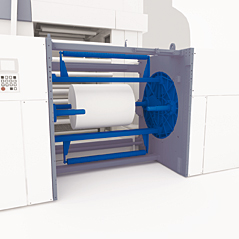

- Roll diameter1000 mm

- Roll handlingshaft / shaftless

- Sleeve technologyyes

Detailed parameters

- Max. Web width850 / 1110 / 1320 / 1500 mm

- Min. Web width300 / 400 / 500 / 600 mm

- Min. Print length300 / 330 / 360 / 400 mm

- Tension range10 ÷ 420 N

- Core diameter76.2 / 152.4 mm

- Roll weight1000 kg

- Solvent-based inksyes

- Water-based inksyes

- UV curable inksyes

- Machine weight45 000 kg

Materials

- LD PE0.020 – 0.160 mm

- HD PE / PP0.012 – 0.100 mm

- CPP0.020 – 0.050 mm

- BOPP, PET, OPA0.010 – 0.025 mm

- Paper25 – 120 gsm

- Film laminate0.020 – 0.160 mm

Main Suppliers

Productivity and efficiency

AC motors in combination with frequency converters provide fast acceleration/deceleration with a working tension as low as 10 N which is important for thin films. Direct drives for printing and anilox cylinders including electronic controls and software ensure reliable gearless technology on well proven applications.

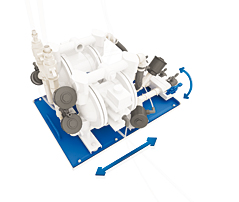

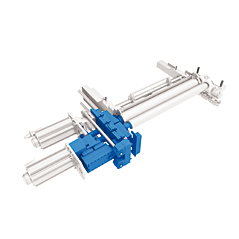

New generation ink pumps are equipped with inking loop for the printing deck and independently controlled twin pumps. This enables suction at ingress and egress to be controlled. Both pumps and valves are located on a sliding platform. By disconnecting the fast action fastenings it is possible to push-off the whole paltform and quickly change this with a spare.

The INKSTORM auto wash-up system ensures perfect suction of residual ink from the complete inking system and minimises ink waste generally associated with traditional automatic wash-up systems. INKSTORM washes the complete inking systém including doctor blade chambers, anilox sleeves, connecting hoses, pumping hoses and filter cage. The system offers several standard washing programmes and individual cycles depending on customer needs. The shortest washing cycle takes three minutes and consumes six litres of solvent. The auto wash-up cycle can run simultaneously on unused printing decks while the press is running a job and significantly shortens make-ready time.

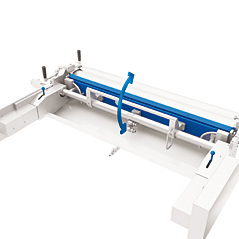

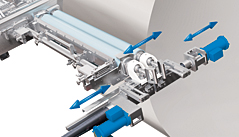

Our patended system of doctor blade housing and self-adjusting chamber setting compensates for doctor blade wear by maintaining a constant angle to the anilox sleeve surface throughout blade life. An unchanged doctor blade geometry ensures longer life depending on blade type and eliminates pressure changes. The self-adjusting setting eliminates the influence of pressure changes in the inking system on the doctor blade chamber position and doctor blade. This also allows the doctor blade chamber to return to its operating position after throw-off.

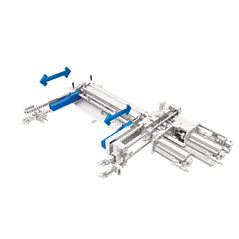

Automatic impression setting and semi-automatic register system. The printing and anilox cylinder support position is automatically set up from printing or by automatic impression setup system. The automatic impression set-up is carried out without printing and with PLATE SAFE function (printing plate protection). The impression setting is achieved without printing so it is possible to go back to the unprinted material and unwind roll and set the register from zero. Longitudinal and cross register positions are automatically set up through the SMART REGISTER system. This system minimises material waste by assessing the static print register marks. The system represents outstanding time saving for new job setting and material saving for short and medium jobs. Total material waste is 50 m.

CDTS is a patented thermal stabilisation system that regulates the temperature of the central cylinder to ambient temperature. This In combination with an electronic pressure compensator that responds instantly to the central cylinder temperature from the machine frame is the greatest guarantee for print stability. This solution ensures accurate permanent print pressure settings independently of changes in temperature conditions around the machine. This system also ensures maximum effectiviness in combination with software recipes where every manufacturing job has its optimum parameters stored, including ambient temperature. When the job is recalled and the ambient temperature does not correspond to the original temperature, the thermal stabilization system automatically compensates for the imbalance and the resulting print is not affected.

Patented thermal stabilisation of the print and anilox cylinders is an important shield against heat acting on sleeves, printing plates and consequently, on the printing dots. Anilox and printing cylinders are affected by the law of thermal expansion as are all other parts involved in the printing process. The greatest source of heat in this case is not only from the cylinder direct drives, but also from the bearings. Our patented system is based on the principle of automatic temperature control according to the frame temperature. This leads to the elimination of any dimensional changes of the printing sleeves as a result of thermal expansion from drive temperature loss. Another possible source of heat affecting the print sleeves is between the deck drying heads. The thermal stabilisation system totally eliminates the influence of hot air to the printing plates. The main benefits are constant print sleeve diamter and print pressure that ensure the same print quality through the software menus and recipes.

Operator comfort

The doctor blade chamber design allows very simple exchange within the machine by turning an excentric key located at the at its side. This concept makes changing blades and seals a simple and fast operation. Simple design and a non-stick surface allow easy doctor blade chamber cleaning. The patented, non-stick nano technology surface, POSITEC was developed in cooperation with the Research Institute and Technical University in Czech Republic. It is a surface film based on PTFE with excluded nano dispersions affecting mechanical and physical surface film characteristics. The main objectives were on chemical resistance, surface tension and wear resistance.

The INK READY system allows anilox sleeves changes and new printing job set up on free printing decks during machine operation significantly reducing changeovers and make-ready times. The INK READY system permits wash up, anilox sleeves and filling of the ink containers on print units not in use during machine operation.

A pneumatic device for easy printing and anilox sleeve push off simplifies handling and access for the operator. This significantly accelerates job exchange and increases operator comfort.

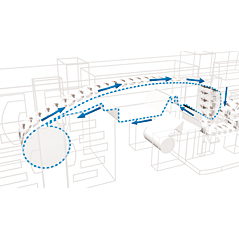

A motorised chain system from dance roller at unwind to the inspection area simplifies web threading throughout the machine. Motorised threading is an efficient solution for operators saving time during job changes or web breaks.

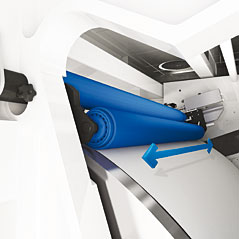

Shaft-less units are an efficient solution for roll handling at unwind and rewind. Rolls are fixed through pneumatic expanding chucks on pulling supports. A quick laser guiding system simplifies roll placement.

The automatic CI drum cleaning unit efficiently eliminates ink, dust and chemical agents that may affect print quality and minimises operator intervention. The cleaning unit operates during machine run and does not require machine stop. The unit is programmable for specific areas on the CI drum and cleaning solution and paper consumption are minimal. Both water and solvent-based inks can be managed.

The JOB MANAGEMENT feature is recommended software for our flexographic printing presses and is an efficient tool for job preparation and recipe storage on an external PC.

The machine is equipped with a recipe system for job file storage as standard. Frequently used parameters such as speed, acceleration, tension, impression, wash-up cycles etc, are stored and accessed via touch screen. Up to 1000 jobs can be stored in the system for recall as and when required. In combination with the Q-Shield feature, the recipe system is an efficient tool for minimal time waste during job exchange.

Print quality

This system provides precise tension control to individual web path zones in the machine depending on the type of material being processed. The system is designed to process a wide range of substrates within a tension range of 10 – 420 N. Tension zones are divided into five sections: Section A. Unwind tension control. Any tension deviation in the material from the correct value is detected by a change in the dance roller position and before any affect on print quality. The control unit decreases or increases the braking torque of the AC servo motor. Section B. Tension control before printing. Tension is controlled through a set of a lay-on rollers and direct drive roll. This in-feed unit is integrated with corona treatment and ensures print length accuracy. Section C. Tension control around the central drum from the drying tunnel to the cooling unit is through PLC and tenso-metric roller that continuously measures the actual tension value. The tenso -metric roller is located just before the first cooling cylinder. Precise values measured at this point are compared by software to pre-set tension values and based on detected deviations. Tension is adapted through adjustment servo motor torque driving both cooling cylinders. Perfect tension control in this zone enables stabilisation of the camera image and eliminates creases or side movement of the web. Section D. Tension control from cooling to rewind unit. Tension is controlled by lay-on rollers and a direct drive roll capable of generating various tension values. This out-feed system is a recommended option for in-line slitting. Section E. Rewind tension control. Tension deviations of the web from the correct values are detected by a change of the dance roller position and before any affect on rewind quality, the control unit decreases or increases the braking torque of the AC servo motor.

Sleeved spreader and lay-on rollers keep the web in constant contact with the CI drum and eliminate air trapping and wrinkles. Exchangeable sleeves permit the use of different durometer rubber hardness for processing different materials.

All key press parts are designed with great emphases on dynamics. Cast-iron side frame consists of four mono-block side frames with two supporting stands ensuring rigid support of the CI drum and cast-iron housing. Side frame thicknes is 80 and the supporting stand thickness is 375 mm at its base graduating to 120 mm at its top. Printing decks with printing and anilox cylinders are ergonomically designed with emphasis on rigidity, precision, reliability and single-hand operation of the printing deck support. Precison and reliability is ensured by linear guide roller, double preloaded ball and screw and double row needle bearing for both cylinders. The number of mechanical parts that can influence production tolerances have been reduced and those remaining optimised for stability.

An electronic stabilisation system compensates for impression with speed changes according to defined curves.The DYNAMIC IMPRESSION feature uses the same motors as those used for the print impression setting process.

The printing cylinder mandrels are made from composite material and have excellent dynamic characteristics enabling quick and higher quality print and the ability to reach 6% shorter print repeat lengths compared to standard jobs.

Safety and ergonomy

A main touch screen control panel with user friendly interface indicates error displays and setting of job parameters. An auxiliary control panel in the unwind and rewind sections ensures quick and comfortable roll handling. The control panels include graphic menu for job parameter settings and diagnostic. The menu is logically and comfortably arranged to display the correct position in real press time. Dedicated screens are connected with the main menu through colour codes.

Modern compact design with aesthetic and ergonomic features maximise operator comfort and minimise accident risks. All eletrcial cabinets are integrated into the machine layout minimising space requirements.

The machines are designed with maximum emphasis on operator safety. All rotating elements are secured by safety covers and are inaccessible to the operator during the operating cycle. The unwind and rewind areas are secured by a laser scanning gate and the printing unit area is safety locked during machine run.

Machines comply with and meet stringent European safety standards and codes. Operation and operator risk analysis are regularly assessed. Safety design elements are updated and new elements are added according to actual standards and code modifications

The main machine parts – drying tunnel, printing unit and fans are insulated with an innovative, new insulation materials to significantly reduce noise and energy consumption.